Energy Storage Integration and Deployment

Project Lifecycle

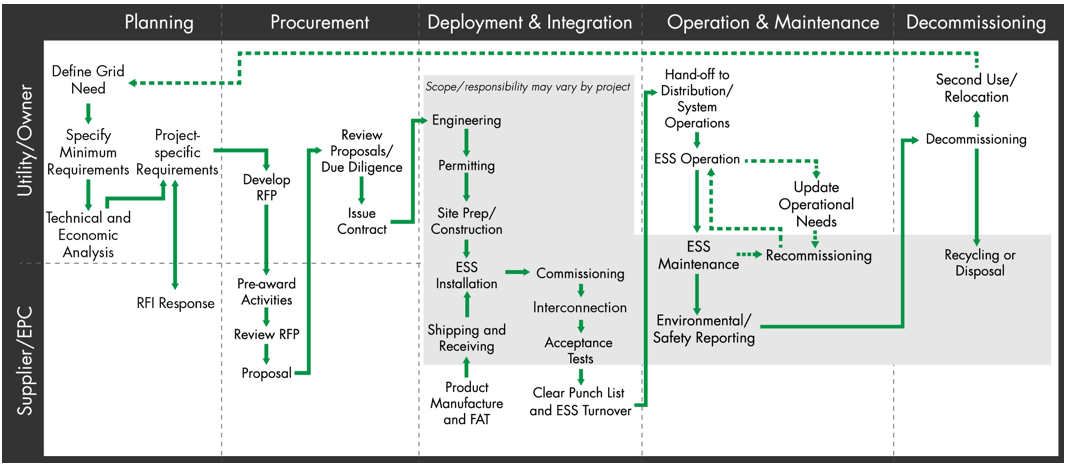

This page walks through key considerations throughout the life of an energy storage project. The contents are excerpted from the ESIC Energy Storage Implementation Guide. The full report includes a more detailed discussion of these topics.

Planning

Planning describes the process for identifying grid needs, translating such needs into technical requirements, and analyzing the cost-effectiveness and viability of energy storage projects.

Define Grid Need:

The first phase in the planning process for an energy storage procurement is the identification of grid needs to characterize applications and services. From the perspective of an electric utility stakeholder, there are several ways energy storage could be used to minimize, defer, or avoid costs; to increase reliability; or to increase the operational efficiency of the electric power system. In addition, there are emerging drivers resulting from the adoption of renewable generation.

Specify Minimum Requirements:

Identifying and assessing specific requirements of storage will ensure that project managers evaluate and screen the energy storage technology’s ability to meet solution requirements defined previously.

Technical and Economic Analysis:

At this part of the planning phase, there could be multiple options to meet the grid need, including conventional options. The decision makers may narrow the scope of options using a screening cost–benefit analysis. This analysis may include secondary service benefits and costs, in addition to those associated with solving the primary service. Processes such as net market value, a metric that considers the net costs and net benefits of a new generator, and tools such as the Electric Power Research Institute (EPRI) Storage Valuation Estimation Tool (StorageVET) product, a cloud-based energy storage valuation analysis tool, help planners perform analysis on the initial cost-effectiveness screen of the options available.

Project Specific Requirements:

Elements for developing energy storage specific project requirements include ownership of the storage asset, energy storage system (ESS) performance, communication and control system requirements, site requirements and availability, local constraints, and safety requirements.

Procurement

Procurement describes the phase of the project that turns previously defined minimum requirements from the planning stage into specifications that result in a formal request for proposal (RFP) or request for offer (RFO). The project team will then review the ESS proposals accordingly and evaluate how well individual proposed systems can meet project needs.

Develop RFP:

A significant portion of developing an RFP is the development of the scope of work for the project. The scope of work is the process in which the utility, or the buyer, has the opportunity to define the objectives of the project and include specifications of the ESS, the energy storage product, balance of system, and other physical components and services that are required for the complete integration of the project. It should also clearly describe the expected responsibilities of each party for procuring, designing, and installing different components in the project. To clearly delineate responsibilities and interactions within each task, a division of responsibility (DOR) matrix should be a key supplement to the RFP. Additional ESIC guides and tools to support the development and clear communication of RFP requirements include the ESIC Energy Storage Request for Proposal Guide, the ESIC Energy Storage Cost Tool and Template, the ESIC Energy Storage Technical Specification Template, and the ESIC Energy Storage Safety Guide.

Review Proposals and Due Diligence: Proposal responses may include a broad spectrum of potential technologies, configurations, and potentially even supplemental value streams in addition to the core solution being sought by the utility. A well-formed RFP with established criteria for evaluating proposals can simplify the proposal review process. For example, use of the ESIC Technical Specification Template allows the buyer to evaluate and compare technical specifications from potential bidders by requesting the same set of technical information within the same reporting format. Other evaluation criteria may include cost, prior deployment experience, financial stability, and other risk mitigation considerations.

Deployment and Integration

Deployment and Integration describes the stage after procurement contracting has been done until the project has been installed and commissioned, and subsequently handed off to operations. Because energy storage technologies are still emerging, the scope of deployment and integration has not always been fully considered in previous stages. To improve the estimates of time and cost required for implementation, it is important to address in detail the steps required at this stage.

Engineering: Site and system engineering will use contract technical specification requirements and utility and industry design codes and standards as the basis of design.

Permitting: It is important to engage local authorities having jurisdiction (AHJs) to understand permitting requirements and additional codes and standards applicable for the construction and operation of an energy storage system. Due to large gaps in standards for energy storage with respect to codes, standards, and regulations (CSRs) and the lag time for AHJs adopting new CSRs, there may be a need to educate and discuss concerns and requirements for safety, nuisance, or environmental issues with certain departments within an AHJ.

Site Preparation and Construction: After a permit or notice to proceed with construction is issued, site preparation and construction can begin.

Product Manufacture and FAT: In parallel with detailed engineering and site preparation, the energy storage product will be manufactured. When the product manufacturing is complete, it is a common practice for the utility or a third party to witness a factory acceptance test (FAT) at the vendor’s manufacturing facility prior to shipment. The FAT is typically a set of quality control–related tests to help ensure that the components of the ESS have been built to specifications before leaving the factory.

Shipping and Receiving After the ESS is approved for shipment, it is transported to the site. Product shipping and receiving procedures, loading and unloading equipment and practices, modes of transportation, and other considerations should be given careful thought. Responsibility for these tasks should be defined during procurement.

Installation: ESS product installation and system integration can be performed by an electrical contractor who should be experienced in both high- and low-voltage systems and familiar with the local electric utility’s system. However, they may be unfamiliar with energy storage technology and require sufficient training and documentation to ensure that the contractor knows about safety hazards and procedures unique to ESSs.

Commissioning: After the installation and connection of an ESS to the distribution system, commissioning is required to ensure successful integration. The ESIC Energy Storage Commissioning Guide provides details of commissioning and site acceptance tests during the deployment and integration phase.

Interconnection: Before the ESS is allowed to interconnect with the grid, tests and documentation may be required to ensure compliance with interconnection standards.

Acceptance Tests: Additional tests, such as performance and control functionality tests, may be required to verify that the system operates as expected. The ESIC Energy Storage Test Manual, with its detailed test protocols that include measurement and calculation methodology, testing duty cycles, and templates for data collection, can be used for acceptance testing.

Operations and Maintenance

Operations and Maintenance (O&M) provides an overview of the various processes steps required over the operational life of the system. Because many of the planning assumptions for the project may evolve over time, it is important to consider both current and future needs while assessing and communicating the inherent strengths and limitations of energy storage technology.

Handoff to Operators: During handoff, it is important that the distribution system and energy resource operators (and other parties with control of storage system) are well-informed and trained regarding the storage system operational software, the intended use of the product, the protection systems and schemes invoked, the planned operational profile of the storage system, and the safety plan.

Maintenance: Maintenance of any asset comes in two forms: planned and unplanned. Planned maintenance should be scheduled regularly, depending on configuration, usage, updates to firmware, and the technology of the ESS, with regular diagnostic checks for indicating degradation and performance expectations. Although costly, unplanned maintenance is needed when storage system malfunctions occur, which may lead to power system reliability issues. Many instances of unplanned maintenance should be avoidable through planned maintenance and diagnostics on system state of health.

Environmental and Safety Reporting: Depending on the type and size of the storage system used, there may be an ongoing requirement to report chemical content, operational status, and other parameters to AHJs.

Update Operational Needs: If changes in operation needs are identified, modeling and simulation efforts may help to understand both the future demand and the current operating needs of the system for energy storage projects. Changes in operation outside the warranty provision or agreed-upon use case may need to be discussed with the vendor or supplier.

Recommissioning: Situations involving replacement of major system components, which could include firmware updates, and changes in operation outside the original scope, may require recommissioning of the system. In addition to recommissioning, periodic performance testing may be conducted to ensure compliance with warranty or to document performance over time.

Decommissioning

Decommissioning and End of Life describes the consideration of issues during the last phase of the project lifecycle when the system is no longer viable. The end of life can be expected by a predetermined project end date, triggered by safety or reliability issues, or caused by exceeding marginal costs relative to marginal benefit. A well-defined end-of-life condition for the energy storage project can ensure the safety, reliability and cost-effectiveness of the project.

Decommissioning: The cost and specifications of decommissioning should be considered throughout all phases of the life cycle. When the decision to decommission an ESS is made, a comprehensive decommissioning plan should be prepared to ensure a safe, efficient process.

Recycling or Disposal: As part of the decommissioning plan, it should be determined what will happen to the system after it leaves the site. A plan could be made to recycle and dispose of the system components or, if there are components that have useful life, they could be reused at another location.

Safety

Energy storage safety should be considered across the entire project lifecycle. The figure below shows key elements in each phase.

Challenges

Key challenges include:

- Adoption of Codes and standards takes time

- Misinformation about fire safety hazards still encountered

- Benchmarks for comparison between technologies and products are difficult to find

- Disparate perspectives of diverse stakeholders expose gaps in responsibility

Codes and Standards

| Standard | Description | Recent Edition |

| NFPA 1 Fire Code | Chapter 52 includes ESS installation requirements (spacing, fire suppression, ventilation) | 2018 |

| NFPA 70 National Electrical Code | Article 706 Energy Storage Systems | 2020 |

| IFC 2021 Fire Code | 2018 version had new chapter on energy storage – 2021 is supposed to align with NFPA 855 | Under development |

| UL 9540 Energy Storage Systems and Equipment | Product safety standard for an ESS: system level; References numerous other standards | 2020 |

| UL 9540a Fire Safety Testing Protocol | Provides test procedure for fire safety and thermal runaway propagation | 2019 |

| IEEE C2-17 National Electric Safety Code (NESC) | New material inserted relating to Storage Safety | 2017 |

| NFPA 855 Standard for the Installation of Stationary Energy Storage Systems | *“Establishes criteria for minimizing the hazards associated with Energy Storage Systems”

|

2020 |